Safety precautions

1.The tail lift must be safely operated and maintained daily by a specially-assigned person after training.

2.It is strictly prohibited for other personnel except the operator to lift or lower the tail lift;

3.It is not allowed to hand over the tail lift to the operator who is not skilled at operation;

4.Single-person operation is for the operation of the tail lift; it is strictly prohibited to use both an electric control box and a wire controller for control at the same time;

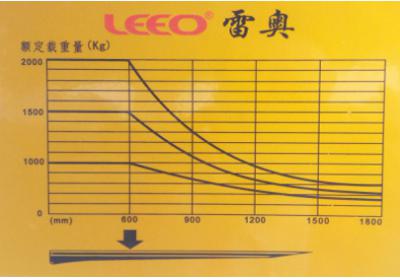

5.Strict prohibition of overload: the maximum lifting capacity indicates the maximum bearing weight when the the distance between center of gravity of goods and the back end of the platform plate is 600 mm, and in the position of 1/2 of platform plate width. The bearing curve of the tail lift (see Fig.1) indicates the relationship between the cargo gravity distance and carrying capacity, so please strictly abide by the bearing curve to carry cargoes, and strictly prohibit overload (whether be static or make motion); otherwise, a damage will be caused to you and your cargoes and equipment;

6.The operator must focus attention on the running condition of tail lift when operating the tail lift;

7.Cargoes must be put stably on the tail lift, and corresponding measures must be taken to prevent the cargoes from moving backwards or forwards in the lifting or lowering process of tail lift. When a hand-press forklift is used, pressure of the forklift must be released before cargoes are loaded or unloaded via the tail lift;

8.It is strictly prohibited to adjust the angle of platform plate in the process of carrying cargoes; namely, it is strictly prohibited to push the button "TURN" in the process of cargo loading and unloading;

9.When the tail lift is in service with cargoes on it, it is strictly prohibited for any personnel to stand on the tail lift;10.Anybody shall not enter into the working area when the tail lift is in service; it is strictly prohibited to hang about within the working range of tail lift;

11.Try to avoid stopovers during the lifting or lowering process of the tail lift;

12.First make sure of reliable van braking before using the tail lift to load or unload cargoes, to prevent the sudden slide of a van;

13.It is prohibited to use the tail lift in a place with a large gradient which is soft, uneven, or with obstacles.

14.It is strictly prohibited to make operation via the tail lift when the vehicle-mounted storage battery voltage is lower than 75% of rated voltage;

15.We must carefully make operation when the platform plate is being lifted or its doors are being closed, to avoid the platform plate contacts with the van body, damaging the van body or the platform plate;

16.After collision or unforeseen events, please carefully check all positions; do not use the damaged platform plate, and please immediately notify the company for repair;

17.Do not overexert on the non-slip mechanism of tail lift, to avoid damaging the mechanical structure; please keep the non-slip mechanism clean to prevent foreign bodies from entering into the non-slip mechanism, causing the consequence that the mechanism can't be used normally;

18.The tail lift should receive a routine inspection every week; the key inspection points: the load-carrying welding position to make sure of no fissure, and all axes of rotation to make sure of no displacement.

19.Make a daily inspection on hydraulic pipeline to make sure it doesn't become loosened, damaged, has no oil leak or seepage; all set screws on the van body to make sure they don't become loosened; electrical circuits and all joint connection to make sure they are in normal order; the hydraulic pressure oil mass in the oil tank to make sure oil capacity in the oil tank is not less than 2/3 of tank capacity when the platform plate is landed on the ground. If you have any problem, please contact us promptly, so that effective measures shall be taken to solve the problem.

20.When the tail lift is out of service, please be sure to turn off the main switch of tail lift, lock up the cover of electric control box, to prevent dust, rain, or other sewage from entering into the control box. Supposing that relays and contactors are damaged due to long-term live work after the main switch fails to be turned off promptly, even that they are burned up due to long-term operation of starters and motors and oil pumps after malfunction, our company will not provide guarantee repair.

21.On condition that fragile articles (such as computers, eggs, or glass) are loaded or unloaded, the lowering speed shall not exceed 6 cm/second.

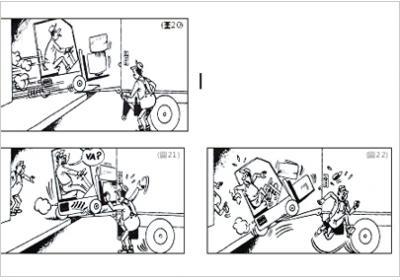

22.On condition that tail lifts of two vans need to be connected for operation, the tail lift of a van must be completed overlapped on that of the other van, to avoid triggering safety accidents. (See Fig. 2)23.A forklift is not allowed to enter into a van via a standard tail lift, but if a fork lock is mounted, a 1.5-ton forklift may be allowed to operate on the tail lift. (See Fig. 3)

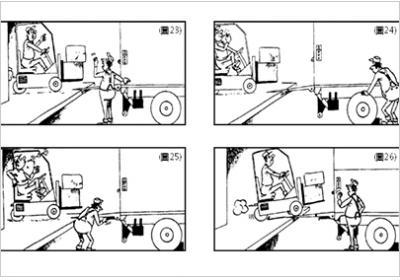

24.When a platform plate connects with a cargo platform, we may lock them via a fork lock to strengthen the strength of tail lift. Wood bricks may be put in the position as shown in the figure when cargoes are loaded or unloaded, to prevent vans from sliding. (See Fig.4)

Special tips:

1.To ensure the safety of equipment and personnel, the operator must completely know about functions and possible danger of the tail lift, maximum cargo weight and carrying capacity. Please do not allow other personnel except the operator to operate the tail lift;

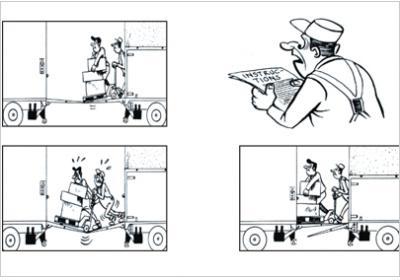

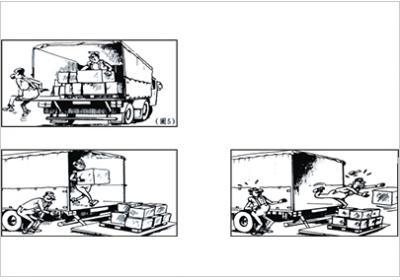

2.The tail lift must be operated and maintained by professionals who have received training. Single-person operation is required for the operation of the tail lift; it is strictly prohibited to let others (the second person) to lift or lower the tail lift outside a van, while you are at work inside the van. Do not result in major damages due to wrong use of the tail lift; (see Fig. 5)

3.When the platform plate is in a wrong position, the plate shall not be retracted, to avoid being damaged due to a collision;

4.The operator of a tail lift shall take all responsibility for all danger. Please make operation and maintenance in strict accordance with requirements ad stipulations, and strictly prohibit overload; otherwise, it will be your liability for any equipment accident and personal injury.

5.Make inspection and maintenance of any visible damage; replace damaged components and parts; please immediately make maintenance for any crack in the parts related to lifting and lowering and turning of the tail lift.